This morning I went to sharpen my pencil in the automatic pencil sharpener and each time I pushed it in and pulled it out, the lead fell out. Frustrating! My 11 year old son, Bradenn, overheard my despair and said, “Come on Dad, don’t you know you have a bad pencil?”

This morning I went to sharpen my pencil in the automatic pencil sharpener and each time I pushed it in and pulled it out, the lead fell out. Frustrating! My 11 year old son, Bradenn, overheard my despair and said, “Come on Dad, don’t you know you have a bad pencil?”

Well just for the record, I didn’t know there was such a thing as a “bad pencil.” Is that like a bad apple? Or a lemon for a car? So I got to thinking, how is a pencil even made and how do bad pencils get made? And since I have been working in and around the wood business for 30+ years, maybe I should find out!

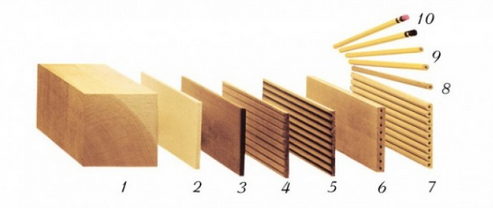

Actually, pencil making is a very interesting process (not like basket weaving). The story begins in the forest, or more specifically in a forest that grows incense cedar trees. These trees are harvested and then logged into “pencil stock.” The logs are then transported to a mill referred to as a slat factory where a block is processed, the length being slightly longer than a standard pencil. Blocks are then resawn to a much thinner blank to eliminate waste and prepare it for grading, waxing and then staining. These factories don’t usually make the actual pencils, so now are blocks are shipped out all over the world to “pencil factories.”

Pencil factories run the blanks through a molder to shape the blanks into grooves that allow a slot for a lead core. These cores are almost always a mix of graphite and clay. A second grooved blank is then sandwiched with the first blank, and sent through a shaper machine that produces hexagon, round and triangular shaped pencils. Finally, the individual pencils are painted, cut to length, and an eraser is crimped on with a ferrule (the metal ring on end).

So there you have it, the unfolding story of the pencil. I’m still not quite sure why my pencil this morning was “bad,” but hey,

sometimes in life, you just get a bad pencil!